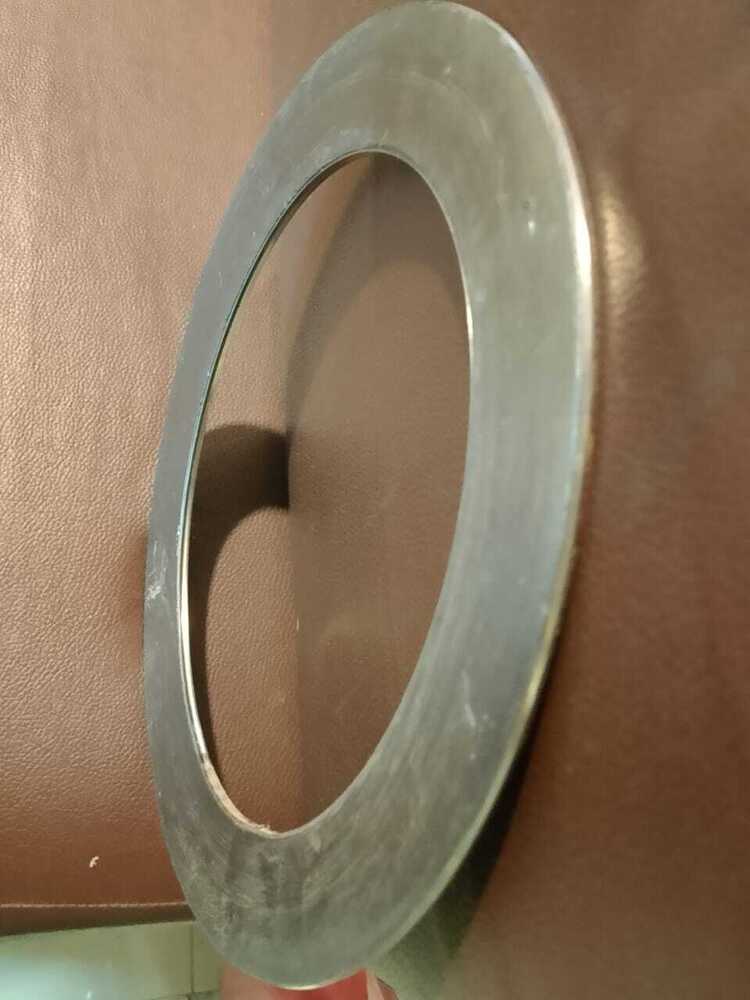

Spiral Wound Gaskets

28.0 INR/Piece

Product Details:

- Temperature Resistance Up to 550C

- Working Temperature -200C to +550C Celsius (oC)

- Medium Other

- Pressure Resistance Upto 250 bar

- Hardness 85-95 HRB (Ring)

- Gasket Coefficient m=3.0, y=10000 psi

- Standard ASME B16.20, EN 1514-2, DIN 2632

- Click to View more

X

Spiral Wound Gaskets Price And Quantity

- 5 Piece

- 28.0 INR/Piece

Spiral Wound Gaskets Product Specifications

- 1-5 Inch

- Other

- Rubber

- 85-95 HRB (Ring)

- Upto 250 bar

- Pipelines, Flanges, Pressure Vessels, Heat Exchangers

- 1-5 Millimeter (mm)

- -200C to +550C Celsius (oC)

- Up to 550C

- ASME B16.20, EN 1514-2, DIN 2632

- m=3.0, y=10000 psi

- Carbon Steel, Stainless Steel (304/316)

- Ring Gasket

- Carbon Steel, Stainless Steel (304/316)

Spiral Wound Gaskets Trade Information

- 5000 Piece Per Week

- 1 Week

- No

- All India

Product Description

By applying modern technologies and innovative ideas, we are able to manufacture and export a large collection of Spiral Wound Gaskets. These gaskets are known to tolerate temperature fluctuations, high pressure and temperature differences. All these products are made with the capacity to maintain the firm seal under uneven and variable loading. Known for their high strength and appropriate dimensions, the range of Spiral Wound Gaskets is highly demanded diverse sealing applications.

Robust Design Ensures Reliability

These spiral wound gaskets use alternating layers of metal and filler wound spirally for enhanced performance. Their smooth or beveled edge profiles make installation straightforward, while high compressive strength guarantees reliable sealing even under demanding conditions.

Wide Application Spectrum

Designed for use in pipelines, pressure vessels, flanges, and heat exchangers, these gaskets handle a variety of mediums, including steam, oil, gas, and chemicals. Available in sizes ranging from 1 to 5 inches and thicknesses between 1 to 5 mm, they suit many industrial settings.

Exceptional Resistance and Safety

With excellent corrosion and temperature resistance, these gaskets function dependably in environments ranging from full vacuum to 250 bar pressure. Their metallic construction (carbon steel or stainless steel) and high hardness provide long-lasting, safe operation.

FAQs of Spiral Wound Gaskets:

Q: How are spiral wound gaskets installed on flanges?

A: Spiral wound gaskets are placed between mating flanges and require bolted connections for installation. The smooth or beveled edge profile facilitates a proper fit and tight seal, ensuring optimal performance.Q: What materials are used in the rings of these gaskets?

A: The inner and outer rings are constructed from carbon steel or stainless steel (304/316), offering excellent corrosion resistance and durability. The filler material, typically rubber in metallic silver with black or gray color, contributes to their leak-tight properties.Q: When should these gaskets be used in industrial applications?

A: They are suitable when working with pipelines, pressure vessels, flanges, and heat exchangers that handle steam, oil, gas, or chemicals, especially where high pressure, temperature, and leak tightness are essential.Q: Where are spiral wound gaskets commonly exported and supplied from?

A: These gaskets are manufactured, exported, and supplied from India to industries globally, meeting international standards such as ASME B16.20, EN 1514-2, and DIN 2632.Q: What makes these gaskets benefit critical systems?

A: Their robust construction, high compressive strength, and excellent leak tightness ensure reliable protection against leaks and withstand fluctuating pressure and temperature, safeguarding critical industrial systems.Q: What is the process for selecting the correct gasket size and thickness?

A: Selection depends on flange dimensions, operating pressure, medium type, and temperature requirements. The available sizes range from 1 to 5 inches with thicknesses between 1 to 5 mm, accommodating various installation needs.Q: What is the advantage of using a spiral wound gasket versus conventional designs?

A: Spiral wound gaskets offer superior adaptability to pressure and temperature changes, enhanced sealing performance, and better longevity compared to conventional flat gaskets, making them ideal for demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Spiral Wound Gaskets' category

|

GASKET INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |