Showroom

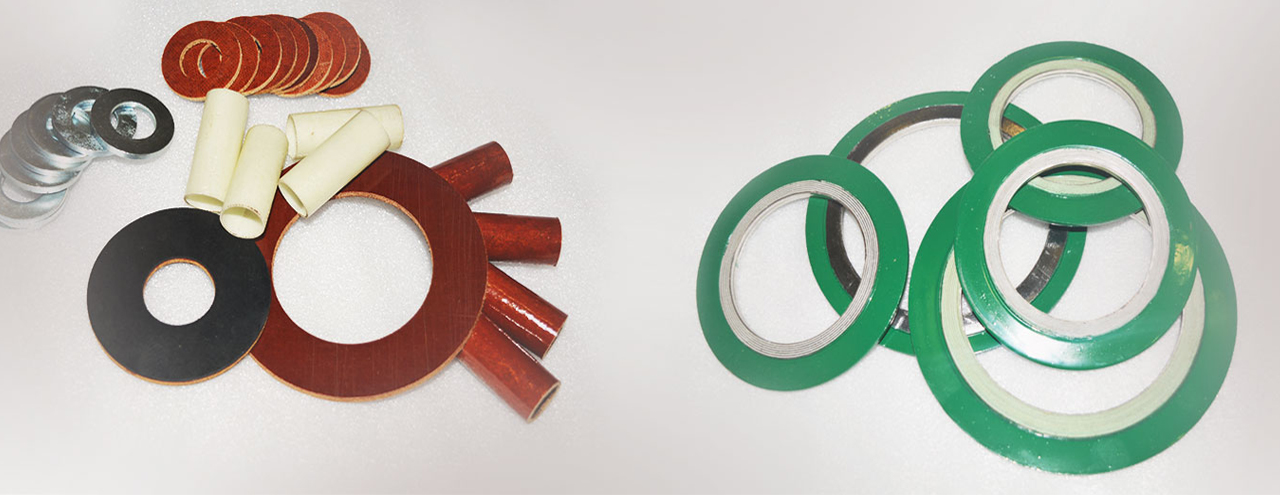

Spiral Wound Gaskets makes the material more buoyant and guarantees that the gaskets are resistant to mould and bacteria. They are ideal for use in a variety of applications for sealing against air, dust, moisture/water, oils, and chemical intrusion.

Metal Gaskets are relatively common components that are utilised in a variety of things, including electrical equipment, pumps, ships, aircraft, and vehicles. They are very effective and economical to use.

PTFE Gaskets are suited for a range of applications thanks to all these features. For product owners, this product benefit reduces maintenance expenses. Another significant advantage of employing this gasket is its long product life, even under constant use.

Ring Joint Gaskets' material must be softer than the flanges' material in order to prevent the flanges from being destroyed. Metallic gaskets are used in high-pressure and high temperature applications.

Non-Asbestos Gaskets have advantages over asbestos gaskets. Typically, compressors, transformers, and low-pressure equipment employ non-asbestos sheets. They require very low maintenance and replacement costs.

Rubber Gasket can be utilised for a variety of functions. To prevent liquid or gas leaks, an EPDM gasket seal caps the intersection of two surfaces and fills the space between two substrate parts.

Gasket can be made from a variety of materials and come in all different sizes and shapes. This is the ideal way to join two surfaces together and fill in imperfections. This is safe to use.

|

GASKET INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |